ইতিহাস ও কার্যাবলী

History of BAPEX

Bangladesh Petroleum Exploration and Production Company Limited (BAPEX) was established in 1989 as the national exploration company by abolishing the Exploration Directorate of Petrobangla with a view to accelerating oil and gas exploration activities of the country. BAPEX was transformed into an exploration and production company in 2000 with a view to making it self-reliant. Currently BAPEX is producing about 110 mmcf gas daily from its six onshore gas fields (Saldanadi, Fenchuganj, Shahbazpur, Semutang, Shahjadpur-Sundalpur, Srikail and Rupganj) contributing to mitigate the increasing gas demand of the country. Besides, exploration and drilling activities in its awarded areas, BAPEX has also been conducting drilling and work-over operations to other sister concerns of Petrobangla since its beginning. BAPEX was awarded exploration block 8 & 11 along with some ring-fenced structures. Oil and gas exploration and development activities are being conducted periodically in these areas.

Functions Of BAPEX

Hydrocarbon potentiality of an area is assessed primarily by conducting geological survey. Based on the findings of geological survey, seismic lines are designed over the area by the geoscientists for the purpose of geophysical survey and acquisition of subsurface data. Based on its expertise, BAPEX has been successfully carrying out 2D seismic survey since its inception. Apart from its own area, BAPEX has conducted geophysical survey for IOCs like Tullow and Chevron under service contract. In carrying out exploration activities, BAPEX has been using multitude of hardware and software such as Geoland Software (field lay-out and QC), Secrel 428 XL (acquisition), RTK, GPS, SOKKIA, Trimble R8GNSS (survey), ProMax, Geocluster (Processing), PETREL (Geological-Geophysical modeling), Tigress, Hampson-Russel and Geoframe (interpretation), PetroMod (Basin Modeling), TecLog (Formation Evaluation). Recently, 3D seismic survey including 3D data processing and interpretation has been successfully carried out by BAPEX with a view to re-evaluating and developing gas fields of BGFCL, SGFL as well as BAPEX.

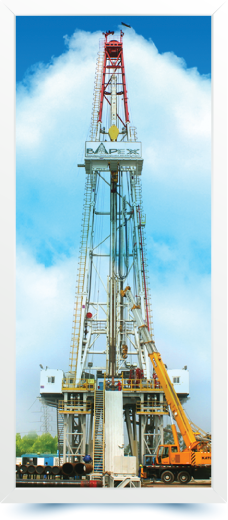

BAPEX has been equipped with four drilling rigs and two workover rigs. In addition, mud engineering, mudlogging, cementing units are also available. Most other services activities necessary for drilling is performed by BAPEX with its own equipment and personnel.

Currently BAPEX is producing about 110 MMSCF gas daily from its seven onshore gas fields contributing to mitigate the increasing gas demand of the country. The Process Plants are designed and operated by world renowned PLC & DCS (ABB / SIEMENS / YOKOGAWA) automation technology. It’s maintenance department is well equipped with modern instrumentation, calibration facilities such as HART Communicator, Process Calibrator, NDT equipment, Gas Detection system, GC, Portable Dew Point Tester etc.

BAPEX has its own Laboratory equipped with modern equipment such as X-Ray Diffractometer (XRD), Polarizing and Zoom Stereomicroscope, Core Measurement (Porosity & Permeability) System, Core Photography System, Gas Chromatograph (GC), Carbon-Sulfur Analyzer, Rock Eval, Atomic Absorption Spectrometer (AAS), Cement Consistometer etc. Gas, condensate and water samples collected from exploratory/development wells drilled by BAPEX are routinely analyzed in BAPEX Laboratory along with samples collected from different gas fields of BAPEX. Core, cutting, outcrop and seepage gas samples are analyzed for important geological data. Obtained data helps to determine reserve of gas fields and thus plays an important role in exploration and development activities of BAPEX. Well cement samples are also tested in BAPEX Lab for well cementation job. Besides, BAPEX Laboratory provides analytical service to other oil-gas companies, IOC, power plants etc. BAPEX has its own core store where core samples and drill cuttings are stored after analysis.